Worldwide. Ready. For You.

We don’t mean to sound pretentious, but some confidence should do no harm, don’t you think so? At least, we from IMS Gear can be convinced of what we have achieved: Over a period of more than 160 years, we have evolved into one of the most popular companies for planetary gears and gearing technology worldwide. But you know what? To be honest, what lies behind us is not even that decisive for us. It’s much more exciting what lies ahead.

With IMS Gear, you count on a global player that has never forgotten its roots in the Black Forest. On highest development competence from A to Z. And not least on a partner that supports you personally with your individual projects. We are ready for you. Always. Worldwide. Sounds great? We think so, too.

Advanced Development

... for us, this also means: consider consequences at an early stage. With IMS Gear, you can definitely count on one thing: That all gear wheels interlock during the development of our planetary gears.

- Calculation bases for gearings

- Development of own software tools

- Development of gearing-specific FEM and CETOL solution strategies

- Comprehensive facilities to simulate, test and analyze in our own laboratory

- Development and validation of modified plastics (IMSamid®) attuned to component requirements

- Close collaboration with universities and institutes

Within the framework of our basic development, we determine material characteristics for:

- Tribology (testing of friction, lubrication and mechanical wear)

- Fatigue strength (Wöhler curves)

- Resistance of media to aging

- Dimensional change under the influence of temperature and humidity

Based on many years of experience in metal and plastic processing, IMS Gear has comprehensive requirements knowledge at its command. The result is an economic and process-adequate parts design that ideally meets the requirements to your desired function. Depending on the scope of development, we support your own development or develop and validate components or gears and can precisely adapt specifications. Depending on priority, we design the gearings according to the following criteria:

- Efficiency

- Increased load capacity

- Insensitivity to axle distance

- Low running noise

- Material-adequate tooth design

You think that sounds like real high-tech? Absolutely!

Product Development

... with IMS Gear, this means primarily the interlocking of proven technologies with customer-specific requirements. In this way, we not only develop suitable products but above all new solution spaces. Based on our many years of experience with metal and plastic processing, we have gained comprehensive requirement knowledge. In the combination of plastic and metal we can ideally reconcile the expectations of our customers in terms of effect, stability, noise development, service life and, last but not least, costs. The result is an economic and process-adequate parts design that ideally meets the functional requirements. Whatever we do is done with full commitment and wide expertise:

- Combination of application knowledge, the use of FEM and moldflow tools and, not to forget, process know-how.

- Conception and implementation of the injection-molding process into practice.

- The quality of the insert parts and the finished product can be monitored 100% in automated injection-molding cells.

- In this way, qualitative, technological and economic requirements can be ideally combined.

It is our aspiration to become part of our customers’ solutions. In doing so, we can develop your development process by:

- Early integration in the development stage of your product

- Analysis and optimization of existing applications

- Design and optimization, prototyping

- Laboratory and testing: noise, function, service life

- Validation

- APQP & FEM – CETOL

- Quality and costs of the development process and the product

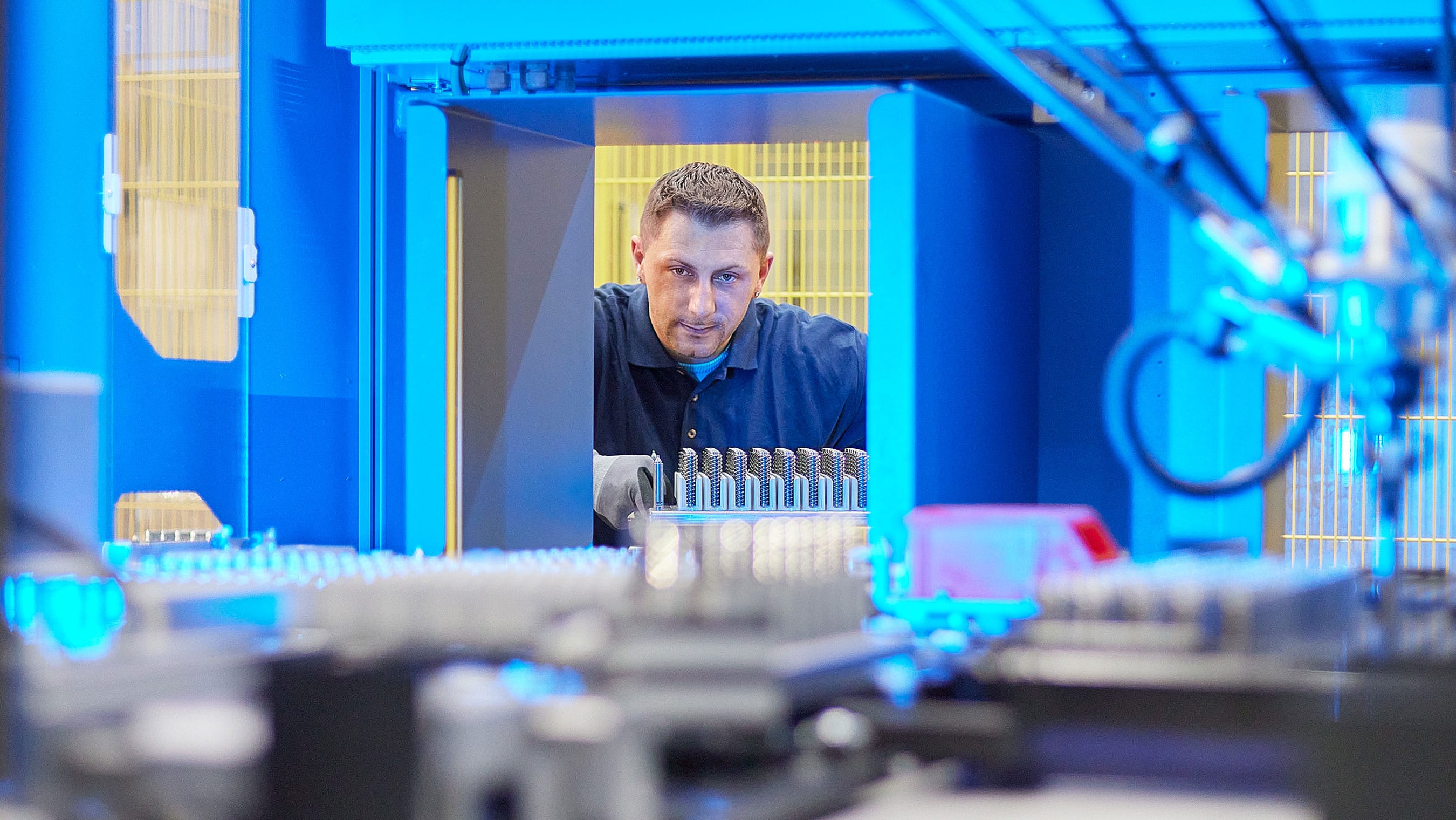

Our products are part of your solution. This includes the proactive search for assembly solutions. Assembly automation and assembly systems are planned and manufactured in our in-house plant construction, allowing us to flexibly react to your requirements. Our manufacturing: in touch with the latest trends. Like our products.

- 100% inline tests for important resp. safety-relevant functional characteristics guarantee a high quality standard of the products.

- Combining our own component manufacturing and assembly reduces interfaces, thus offering the best preconditions for quality and competitiveness.

- Among other things, the component assembly is characterized by the completion of components from our own and third-party manufacturing.

- IMS Gear ensures the coordination of the different parts and applications through its high validation competence.

Processes

... at IMS Gear, this means above all: powerful and proven processes, with maximum vertical manufacturing as an essential element. This not only ensures that all our customers get everything from a single source. But also that inside the company the left hand knows what the right hand is doing.

- Manufacturing of plastic and metal components (incl. heat treatment) up to the assembly of components and gears.

- Closed responsibility

- Consistently optimized design, implementation (APQP) and improvement (CIP) of processes.

- Integrated quality

Our strength lies in the combination: We at IMS Gear are experts in metal, plastic and metal/plastic components:

Metal Processing

The manufacturing of metal gearing components has a long tradition at IMS Gear.

- Turning with vertical or multi-spindle machines

- Centerless outer cylindrical grinding

- Honing

- Roll forming

- Highly precise gearing processes

- In-house manufacturing of own gearing tools as well as treatment and hardening processes

Plastic Injection Molding

The production of precise gearing components, gearboxes and technical plastic parts are core competences of IMS Gear.

- In-house mold making as core element of our plastic processes.

- Standardized and replicable processes: On more than 150 injection molding machines worldwide, we produce precise plastic or plastic/metal components.

- The spectrum of processed materials ranges from non-reinforced engineering thermoplastics to high-temperature plastics.

- Based on globally valid standards of measuring technology, we can manufacture your parts in the same quality at all our locations.

- Due to our own toolmaking, we can react flexibly and precisely to customer-specific demands with respect to component design, process requirements and modifications.

- With up to 32 cavities per tool, the processes are optimized for medium-sized and large series.

- In terms of materials, IMS Gear not only uses reinforced and non-reinforced thermoplastics but also thermoplastic elastomers. High-temperature thermoplastics are processed in special tools that are also manufactured in-house.

International Production

... not only means that IMS Gear has locations all around the globe. But also that you can rely on our quality and competence all over the world.

The replication of proven, standardized processes is the best basis for high quality and competitive costs at locations worldwide.

- Identical processes at all production locations

- For the same product

Good to know: Our strength as a global payer also allows to flexibly build up production capacities with and for our customers. In this way, we transform our performance into your locational advantage. Up for taking off with IMS Gear?