The Hardening Shop of IMS Gear

Hardness Meets Competence – with Experience and State-of-the-art Technology

Robustness, long service life, breakage safety, but also optics: With our hardening shop we from IMS Gear perform the final finishing of turning parts and many other metal components. Apart from processing own parts for the manufacturing of our planetary gears, components for the automotive industry and more, we have been an expert on industrial hardening technology and a popular and reliable partner for a large number of metal-processing companies all over South Germany.

A wide range of different hardening processes with powerful machinery, state-of-the-art testing and measuring equipment, a highly skilled team, decades of experience and expertise, but above all our know-how and comprehensive advisory competence make the hardening shop of IMS Gear in Donaueschingen your perfect service provider. We excel by flexibility, dependability, highest quality, delivery reliability and maximum speed in the implementation of hardening projects. We will be happy to assist you in person concerning your request - do not hesitate to contact us directly.

Convincing arguments - this is what the hardening shop of IMS Gear stands for:

- More than 40 years of experiene in hardening technology

- Comprehensive advisory competence

- Fully-automated hardening processes

- Short, reliable lead times

- Consistent process documentation

- Flexible logistics (incl. collection & delivery of parts)

- ISO 14001 : 2015

- ISO 50001 : 2018

IATF 16949 : 2016

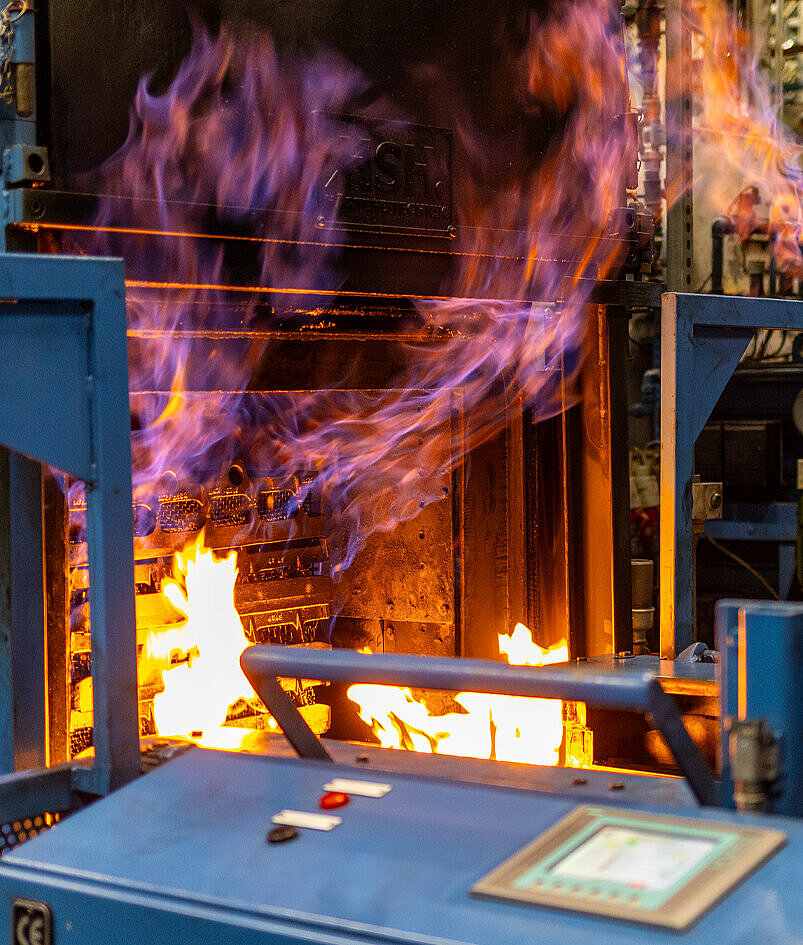

Hardening Technology in a Nutshell

In the hardening shop of IMS Gear we combine state-of-the-art technologies with decades of experience to make metal parts more durable, resistant and powerful. With a wide range of hardening techniques, fully-automated processes and highest quality control we are your reliable partner for demanding heat treatment.

What characterizes the Hardening Shop at IMS Gear in Particular?

For decades, we have made a name for ourselves as a hardening shop in the Black Forest, Baar and Heuberg to the Breisgau and Lake Constance region. Meanwhile, we harden resp. quench and temper a great variety of components for demanding customers in the area. These include numerous metal components for exacting requirements from the automotive, machine-building and hydraulics industry, from craft and household tools and many more industries. Our competitive advantage over other suppliers is the result of three specific factors:

From hardening technique to logistics – here you find the most important information

Which Hardening Processes does the Hardening Shop of IMS Gear offer?

As an experienced and powerful partner and service provider we from IMS Gear offer an extremely wide range of industrial processes for the reliable hardening of all kinds of metal parts. The hardening process is always oriented towards the individual requirements to the respective components. Die IMS Gear hardening shop offers the following hardening process:

- Hardening

- Quenching and Tempering

- Carburization

- Case-hardening

- Carbonitriding

- Blank hardening

- Vacuum hardening

- Nitriding

- Carbonitriding

- Tempering

- Deep-freezing

- Annealing

- Oxidizing

Where are Customers of the IMS Gear Hardening Shop Located?

Every now and then, we are confronted with the question up to which distance from our hardening shop we supply companies. Basically, we from IMS Gear supply customers all over South Germany as a service provider for hardening and heat treatment technology.

Most of them are located in a range of appr. 20 to 80 kilometers. Thus, the hardening shop of IMS Gear acts as a service provider and partner for companies in the Black Forest, Baar and Heuberg up to the Breisgau and Lake Constance area. Special projects have extended (far) beyond this, e.g. for customers in Spain or Portugal.

A particular advantage: With our in-house logistics we are capable of collecting and delivering (very) big orders from and to our customers - flexibly and in a very short time. We will be happy to assist you in person as a reliable partner for professional hardening and the heat treatment of your metal parts.

Which Parts can be Treated in the Hardening Shop of IMS Gear?

Basically, we can subject all kinds of metal parts to professional heat treatment in our hardening shop. As a rule, we at IMS Gear harden a great variety of metal parts such as turning parts, milling parts, gearwheels, gear parts, etc.

What Exactly is Automation in the Hardening Shop of IMS Gear like?

In the hardening shop of IMS Gear, we work with an automated multi-purpose chamber furnace line that allows for a great variety of hardening as well as quenching and tempering techniques. All processes are integrated into a central process control:

- The furnaces in our hardening shop are fed and discharged by an automated transportation system.

- All major process parameters are individually tuned to the specific material and component properties.

- The plant technology is consistently computer-controlled (BDE/PPS) which allows for precise furnace control and a complete process documentation and economic order processing.

Thus, the automation in our hardening shop provides for a maximum degree of efficiency and transparency: Optimum results can be repeated at any time, the individual steps are transparently traceable - ideal especially for components that need to meet long-term consistent qualities in large series.

Which Hardening Furnaces and Plants are Used in the Hardening Shop of IMS Gear?

Flexibility and performance - this is something the hardening furnaces we use in the hardening shop of IMS Gear also stand for.

Protective Gas Chamber Furnace Line

Possible processes:

- Hardening

- Quenching and Tempering

- Carburization

- Case-hardening

- Carbonitriding

- Blank hardening

- Tempering

- Deep-freezing

- Annealing

max. batch weight: 500 kg

max. charge dimensions: L: 900 x W: 550 x H: 600 mm

Vacuum Furnace

Possible processes:

- Vacuum hardening

- Annealing

max. batch weight: 500 kg

max. charge dimensions: L: 900 x W: 550 x H: 600 mm

Gas Nitriding Furnace

Possible processes:

- Nitriding

- Carbonitriding

- Oxidizing

- Annealing

max. batch weight: 1200 kg

max. charge dimensions: L: 1200 x W: 800 x H: 1000 mm

Up to Which Size can the Hardening Shop of IMS Gear Process Parts?

Depending on the size / dimensions the parts are either charged or hardened as bulk material. This means that the hardening shop of IMS Gear can subject even smallest parts to heat treatment. Somewhat bigger parts are charged for the hardening process.

Basically, our hardening shop at IMS Gear covers a very wide range of possible parts and part dimensions for our customers. This starts by smallest parts with a diameter of 1 mm and ranges up to metal parts with a unit weight of several kilograms. You will find more detailed indications in the technical data of our hardening furnaces.

Please contact us directly by mail at haerterei@imsgear.com or by phone at +49 (0)771 8507 - 771 for concrete questions regarding the hardening of your specific parts.

Which Other Services Apart from Hardening does IMS Gear Offer?

In order to ensure the maximum quality of the parts to be hardened and to support our customers before and after the projects as well as possible by our sound expertise, the hardening shop of IMS Gear offers several accompanying services.

These include downstream verifications of the target properties with state-of-the-art testing methods in the in-house lab and further services:

- Materials appraisal / testing (e.g. hardness tests acc. Rockwell, Brinell, and Vickers)

- Advice and process development

- Spectral analysis

- Performing and detailed evaluation of microsections

- Cooperation with external accredited institutes

The process development, documentation, and advice in all matters related to hardening processes and materials selection round off the service range of the hardening shop at IMS Gear.

“The hardening of metal parts is demanding. With us from IMS Gear you count on competence and experience: As one of the most modern hardening shops in Germany we stand for top quality with the additional benefit of speed and advice. Your parts are in the best hands with us - don’t hesitate to contact me in person.”

Christian Schwierz

Head of Hardening Shop at IMS Gear

Get in touch with Christian Schwierz