![[Translate to English:]](/fileadmin/_processed_/3/2/csm_weiteres-tischhoehenverstellung_a93db3e40d.jpg)

Planetary Gears for table height adjustment

A new LevelThe ergonomics at workplaces

In recent years, ergonomics at the workplace has become an ever more important topic. When it comes to innovative solutions for the height adjustment of workbenches, kitchens or workplaces, SUSPA GmbH from Altdorf near Nuremberg counts on a planetary gear from IMS Gear. The specialist for adjustment systems thus takes the quick, noiseless and convenient setting of the desired height to a new level.

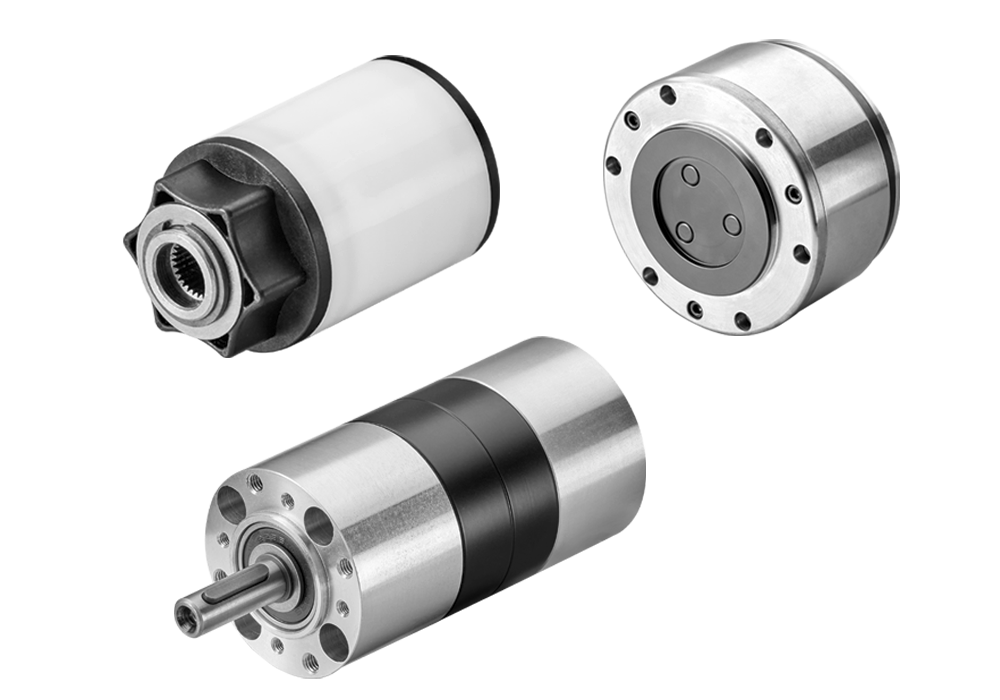

With its modular system, IMS Gear’s spectrum ranges from quick quality solutions to customer-specific adaptations and sophisticated special gear configurations. The same applies to our solutions for modern agricultural technology.

- Compact installation space

- Low noise development

- High flexibility & wide range of applications

“Our idea: What has successfully been realized in the auto-motive field can certainly be transferred to other applications such as the workplace or the kitchen.”

From Street to Workplace

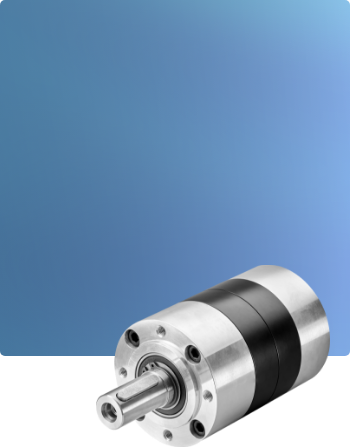

SUSPA and IMS Gear have been working together successfully for decades. To give an example, our planetary gears can be found in spoiler adjustments of mid-range and luxury cars of various manufacturers. At a defined speed, the downthrust aid is automatically extended. The system is driven by an electric motor whose high rotational speed is transformed to the required force by a planetary gear from IMS Gear. The solution from the modular system requires little installation space, so the SUSPA engineers came up with this idea: It should be possible to design an electric height adjustment for numerous applications in the home and industrial area. Thought - said - done!

From Rear Spoiler to Table Adjustment

The motor/gear solution of the spoiler adjustment was chosen as the

starting point. As the installation space in the so far hydraulically driven

Movotec spindle motor system (SMS) is limited to an outer diameter of 35mm, the gear drive had to be adjusted. “Instead of an axial screw connection radial laser welding was utilized. In this way, the outer diameter could be reduced from 32 to 28 mm”, explains Helmut Brugger, Sales Engineer at IMS Gear.This is made possible by the variability of the IMS Gear modular system, while the gear geometry remains unaffected. Unlike at the rear of a vehicle in direct vicinity of a powerful engine at more than 100 km/h, minimizing the noise level is essential level when a workplace is adjusted. “For this reason, both stages of the gear drive feature plastic gear wheels. In view of the high load, the planetary carriers are made of metal”, Brugger explains.The development time, including the complete validation of the new product with such a high power density, should be kept as short as possible.

For this reason, it was an advantage to draw on the modular gear kitfrom IMS Gear. The short time span for a custom-fit gear drive was only possible by using prefabricated gearing components from IMS Gear.

Overcoming the Drawbacks of Conventional Systems Without Loss of Performance

The starting point of the new application was the idea to replace the gas pressure spring systems dominating so far. Their disadvantages include the larger installation space, less precise adjustability and therefore in total a higher integration effort. SUSPA expects that in the long run electrical systems will prevail. For this reason, there is a tendency towards large-scale production. Yet another project reflecting the role of IMS Gear as a facilitator. The recourse to a modular system opens up many advantages for the user: It has the variability to combine a great variety of metal and plastic parts and so achieve the gear reduction desired. The quality and durability of all these parts were already verified in numerous test runs and series applications. Thus, IMS Gear provides design and production knowledge from large series also for smaller starts. As can be seen from the example of height adjustment. In the first stage, the high rotational speed directly meets the gear drive. A noise-reducing plastic helical gearing provides for the first gear reduction there, while the torque is still low. “The exact implementation of the specially designed gearing in this stage is based on decades of experience of IMS Gear in combination with state-of-the-art simulation calculations”, Brugger explains. In the second stage, spur-geared plastic wheels transform the rotational speed into the required torque.Together with the gear technology from IMS Gear, the electromechanic Movotec spindle motor system (SMS) from SUSPA handles high lifting loads of up to 150 kg per lifting column. A DC electric motor with a low-noise gear drive from IMS Gear that turns an interior spindle is integrated into each lifting element with a profile cross-section of just 35 mm. Due to the rotary movement, the non-rotative spindle nut moves in axial direction. In this way, it is directly connected to the guide tube that - depending on the stroke length - can be retracted and extended by 150 to a maximum of 400 mm.

Conclusion

If individual planetary gears become standard solutions, IMS Gear has once again accomplished its role as facilitator. “The recourse to our modular system opens up many advantages for the user”, Bea sums up. “It has the variability to combine a great variety of metal and plastic parts and so achieve the gear reduction desired. The quality and durability of all these parts was verified in numerous test runs and series applications. IMS Gear provides design and production knowledge from large series also for smaller series. This allows to implement numerous further applications in agricultural technology.

Your are looking for a custom-fit solution for your application? Then let’s talk about it: As an experienced development partner, we at IMS Gear are always excited to develop new solutions for the world of tomorrow.

Get in touch with Helmut Brugger

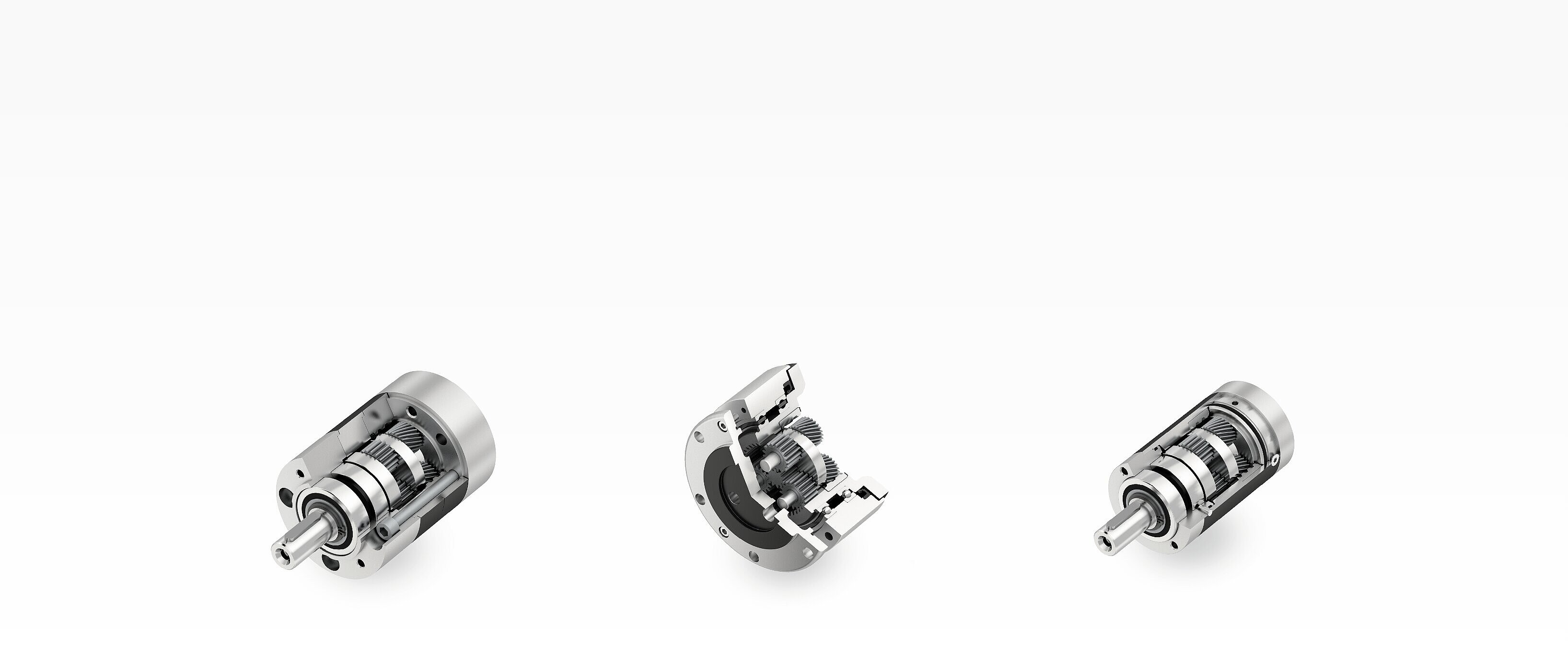

What Is a Planetary Gear?

A planetary gear (also: epicyclic gear) is a technical design that serves as a “link” for power transmission between a drive source (the motor) and an application to be moved (e.g. the movement of a wheel). For many decades, we from IMS Gear have been renowned experts for the design and manufacturing of planetary gears for a great variety of industrial applications.

Where Are Planetary Gears Used?

The advantage of planetary gears is their ability to combine high power density with little installation space. A further important factor is the low noise emission that can be realized by the specific design. This makes planetary gears an ideal solution for a great variety of applications, e.g.

- logistics (industrial trucks, driverless transport vehicles, ...)

- building technology (e.g. automated access systems, barriers and doors), household devices (e.g. robot lawn mowers, appliances, ...)

- agricultural technology / farming (e.g. feeding and milking robots, seed drills, ...)

- and many more.

How Does a Planetary Gear Work?

Basically, planetary gears work as the name implies: the sunwheel is in the center and driven by the motor. It confers its motion to three rotary planetary wheels which form a stage. They are arranged on the bearing bolts of a planetary carrier. The last planetary carrier is rigidly connected to the drive shaft and so provides power transmission at the output. On the outside, the planetary gear wheels rotate in a gearbox with internal gearing, the so-called ring gear.

Input and output are arranged coaxially with planetary gears, the shafts rotate in the same direction. PLGs are suitable for clockwise and counter-clockwise rotation, alternating, continuous and intermittent operation and are characterized by a high level of efficiency. The compact design offers high power density compared to other gear designs and high torque transmission for extremely small installation space.

If the number of teeth of the sun wheel and planetary wheels is changed, different gear reductions are possible within one stage. We from IMS Gear combine the reductions of our planetary gears in up to four stages. In this way, an enormous variety of different gear requirements can be realized.

Why Is the Output Torque of a Planetary Gear so Important?

Output torque is the most important parameter when choosing a planetary gear. The gear reduction reduces the relatively high rotational speed of the motor (rpm), delivering a lower rotational speed at the output end. This increases the output torque in inverse ratio. To link the planetary gear to the respective application a specific connecting flange is required.

As different manufacturers apply different measuring methods, great care must be taken when seeking to make a comparison. We will be pleased to calculate the maximum axial and radial load for your specific application under consideration of all parameters. Higher loads can be achieved through design measures. We will be happy to develop tailor-made implementation concepts for our customers.

Which Motors Can Planetary Gears Be Adapted to?

The connection between driving shaft (the motor) and the planetary gear is highly individual as there is a great number of different motors (and manufacturers) with particular specifications. This is where manufacturers of planetary gears show their degree of flexibility. Basically, all IMS Gear planetary gears can be adapted to fit all motors available on the market; individual solutions are possible at the input and output sides.

How Relevant Are “Operational Dynamics” and “Gear Backlash” for Planetary Gears?

High levels of operational dynamics are achieved through low inertia torques, smooth running and low levels of mechanical wear. When it comes to designing and manufacturing planetary gears, IMS Gear uses plastic instead of metal for the planetary wheels where appropriate and technically feasible. This delivers low inertia torques. If necessary, we achieve smooth running through high-quality needle bearings or low friction coefficients between metal and plastics, low levels of mechanical wear through a special gearing design and the use of plastics wheels. In a nutshell: The material mix typical of IMS Gear ensures excellent operational dynamics.

In this context, the gear backlash of the planetary gear has to be considered. It depends on many factors: Type of load, number of stages, bearing, version, combination of materials. When seeking to compare different manufacturers, always remember that here, too, there are no standardized measuring methods.

Depending on the field of application, the efficiency of planetary gears is also to be specified. The gearing efficiency only takes account of the rolling motion of the gearwheel, the gear efficiency of all losses of the entire bearing. It is inevitably lower than the gearing efficiency. As there are no standardized measuring methods, a comparison of the efficiency levels of different manufacturers always requires special attention. Please contact us if you have any special requirements here.

Which Temperature Ranges Can Planetary Gears Be Used in?

The application resp. operating temperature range of planetary gears depends on the respective application but also on the material and lubrication. Our pure metal versions with standard lubrication range between −30° and +120° C, the Eco Series made of plastic between −15° and +65° C.

Which Protection Classes Do Planetary Gears Have?

The protection classes of planetary gears are defined according to DIN EN 60529. Planetary gears (short: PLGs) from IMS Gear can fulfil the following protection classes:

- Gears with sintered bearings: IP 40

- Gears with ball bearings (2 RS): IP 53

Upon request you can obtain output and motor gaskets to realize higher protection classes.

Which Installation Position Is Possible for Planetary Gears?

Due to grease lubrication the IMS Gear planetary gears can be installed in any desired position. In vertically arranged outputs, additional sealing measures can be provided on request.

What Is the Service Life of Planetary Gears?

Depending on environmental conditions and the operating data of the drive system, the service life of a planetary gear ranges between 200 and 30,000 hours. The great variety of application options precludes any generally applicable forecast of service life.

Planetary gears from IMS Gear are usually lubricated with grease and therefore maintenance-free during their service life. Depending on the requirements profile, we select the optimum lubricant from more than ten options.

The structural conversion through the hardening of the individual metal parts has a positive effect on the strength and wear behavior. IMS Gear has its own heat treatment shop. As the entire metal manufacturing is in-house, we can choose from various steels for hardening.

How Noisy Are Planetary Gears?

Low-noise behavior is a decisive criterion for certain applications of planetary gears. In these cases, so-called low-noise planetary gears are the solution of choice. To achieve an optimum noise behavior, increased demands on concentricity and axial run-out of the motor end plate, flange and shaft need to be met. Axial forces act on the motor shaft due to helical gearing. Sufficient dimensioning of the motor shaft bearings should be taken into account here.

To counteract the grease-promoting effect of helical gears, radial shaft sealing rings or sealed motor bearings can be used. Especially in the field of low-noise planetary gears we from IMS Gear have developed extensive experience and are available as a reliable manufacturer and development partner.