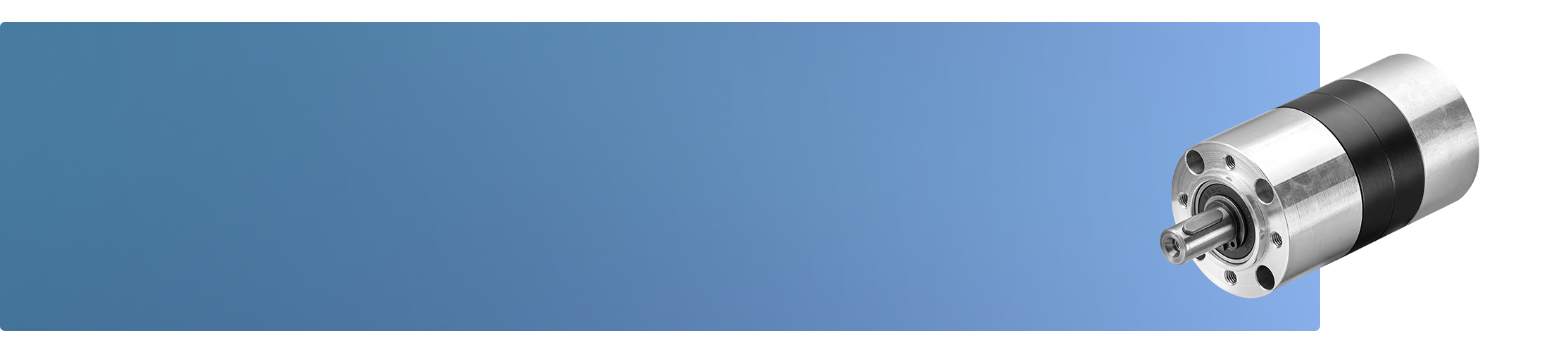

Gear Technology by IMS Gear

As one of the leading manufacturers of gear technology worldwide, our focus has always been on driving and moving forward. For our customers from the automotive and numerous other future-oriented industries, the name IMS Gear stands for reliable solutions and innovative developments. For presence and performance around the world. Above all, however, for the certainty to have a personal partner at their side.

The products and solutions from IMS Gear open up new opportunities for our customers. And thus the progress we all call future. Doesn’t that sound exciting? We have always been convinced that ideas are stronger than boundaries. What seems unthinkable today may be reality tomorrow. We are working on it: Let us shape the world of today and tomorrow. Together.

Believe us when we say:We understand you.

With our wide range of proven components, comprehensive development competence and decades of experience we transform individuality into standard for you. The perfect solution? It’s always the planetary gear that is custom-fit for you. To find it, we start by listening very closely: A common understanding is always the best foundation for successful relationships.

Listening. Understanding. Tinkering. Doing. How can we help you?

Planetary gears as if made for you