Drive is motion? Drive is future! Naturally, we from IMS Gear are at the start as well. With IMS Drive we have developed a series that meets the specific requirements in the field of wheel drives particularly well - with AGVs and AMRs, with golf caddies or solutions for the so-called last mile.

In particular, this includes compactness which we have achieved in IMS Drive by a reduced overall length. With the IMS Drive series, we can easily meet further criteria such as performance resp. troque with a given load, service life or noise emission.

And all this in an efficient cost framework. After all, IMS Drive is also essentially based on our modular system for which IMS Gear is known worldwide.

You are interested in a solution from IMS Gear’s IMS Drive series or would like to realize a project with us? Then don’t hesitate to get in touch; together we will find the perfect way for your individual requirements.

Pretty compact.

Pretty clever

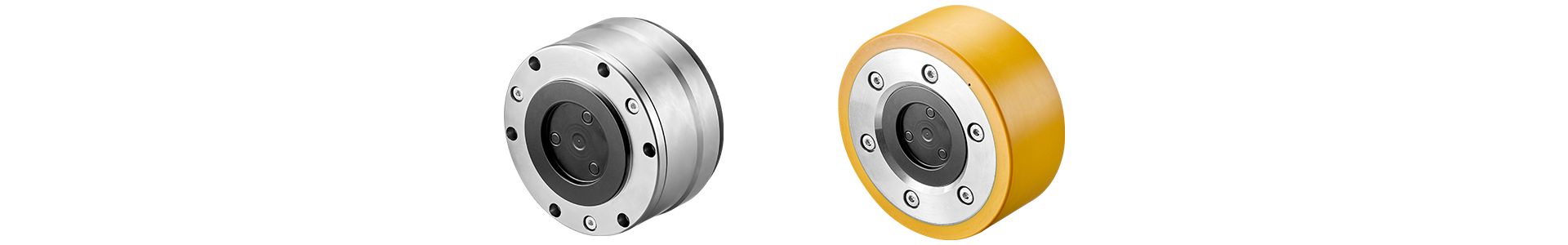

Today’s IMS Drive series is the result of the development of planetary gears focused on the specific requirements of wheel drives. Thus, it is also essentially based on our proven modular system. The engineering focused on the significantly reduced overall length of the gear drive. This development was further differentiated and now forms our IMS Drive series that is geared towards the highly particular requirements typically found in wheel hub drives. IMS Drive is predestined to be used in intralogistics, e.g. in AGVs (Automated Guided Vehicles) and AMRs (Autonomous Mobile Robots). However, these compact planetary gears also convince in golf caddies or last-mile solutions.

The requested powerdensity and the high requirements to service life due to the frequent 24/7 use not only place significantly higher demands on the gearinggeometry but especially on the bearings. This is why the gear solutions from the IMS Drive series by default include planetary wheels with needle bearings.

Ring Gear Optimizations

The length reduction is technically implemented by a specific further development of the ring gear. As the most important component, the ring gear performs several tasks at once and replaces components such as bearing and connecting flanges otherwise typical of planetary gears. In the IMS Drive series, the ring gear itself is manufactured in a single-step production process and, thanks to the direct attachment to the vehicle (respectively, in other applications, to the element to be moved) and the motor, allows for a safe and compact connection. Direct attachment is a proven technical solution from the modular system of planetary gears.

The inner life of the ring gear features the usual setup with elements of the modular system from IMS Gear.

With helically geared planetary wheels in the first step and spur gear wheels in the second step the acoustic behavior is optimized. In order to take maximum advantage of the potential of the reduced installation space, the wheel bearing with IMS Drive is located directly at the outside of the ring gear and does not occupy any axial installation space. Furthermore, the bearing arrangement on the ring gear results in an optimized flow of forces with respect to bearing forces, as the lateral offset between the force transmission and the bearing is omitted or greatly minimized. Thanks to the almost centric alignment of the bearings and the tread of the wheel no leverage is created. This, in turn, minimizes the load on the wheel bearings and positively influences the service life.

IMS Drive - Highest Compatibility and Easy Assembly

With IMS Drive, you put the power to the pavement, no matter if in your automated manufacturing, in intralogistics or in further applications. This also involves ease of implementation. Due to the standardinterface to the wheel, the approach of the planetary gears from the IMS Drive series can essentially be realized with all wheel manufacturers.

Summary

With IMS Drive, a product line of planetary gears was developed that offers answers to the specific requirements of wheel drives - on a large and small scale. Powerful, highly compatible, and easy to install, IMS Drive convinces on all levels: In this way, our customers’ power is put to the pavement, no matter whether in traffic, in the dynamic world of intralogistics or in other areas.