You want to add future to your production?

We understand that well. After all, we from IMS Gear have long been at the forefront of developing intelligent automation concepts for the manufacturing of complex small parts. We will be happy to use this competence to your advantage!

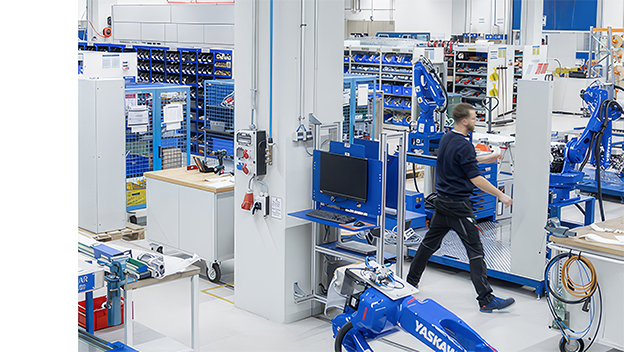

Something many people don’t know: With our division “Industrial Engineering Automation” - in short: IEA - we are not only an in-house service provider for automated production processes of our Automotive and Industrial divisions. We also assist external customers with our expertise. Let us talk about your individual requirements!

Let’s Talk About Efficient Automation

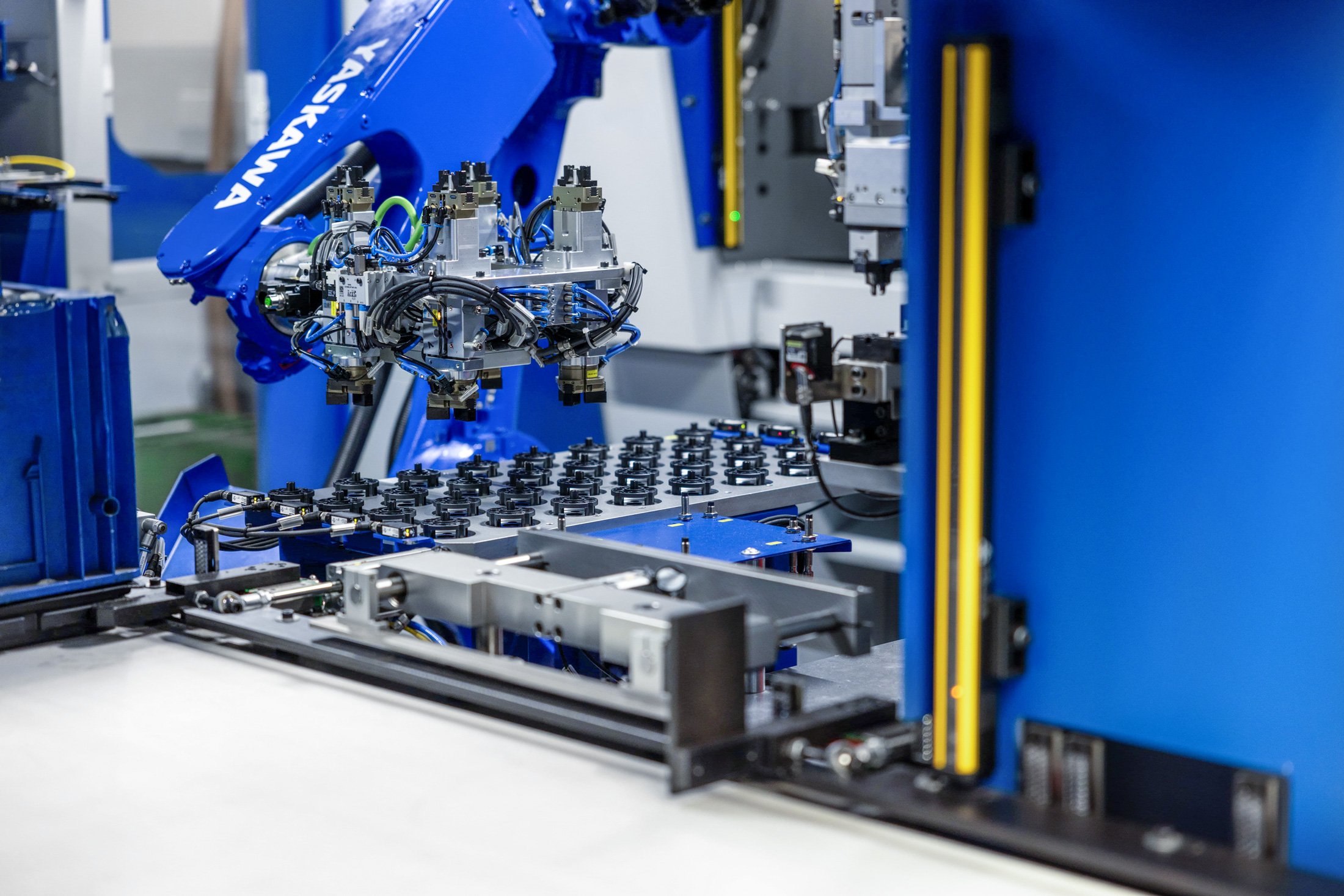

Efficient automation processes in metal and plastic production - naturally, this does not only relate to the actual manufacturing and processing of workpieces. The upstream and downstream periphery also plays a major role: From loading and unloading and the transportation of parts to a variety of testing and measuring processes.

For all of this, we from IEA not only have a wealth of experience at our disposal but have also developed proven, tested, and above all customizable process modules.

The Three Columns of our Automation Competence

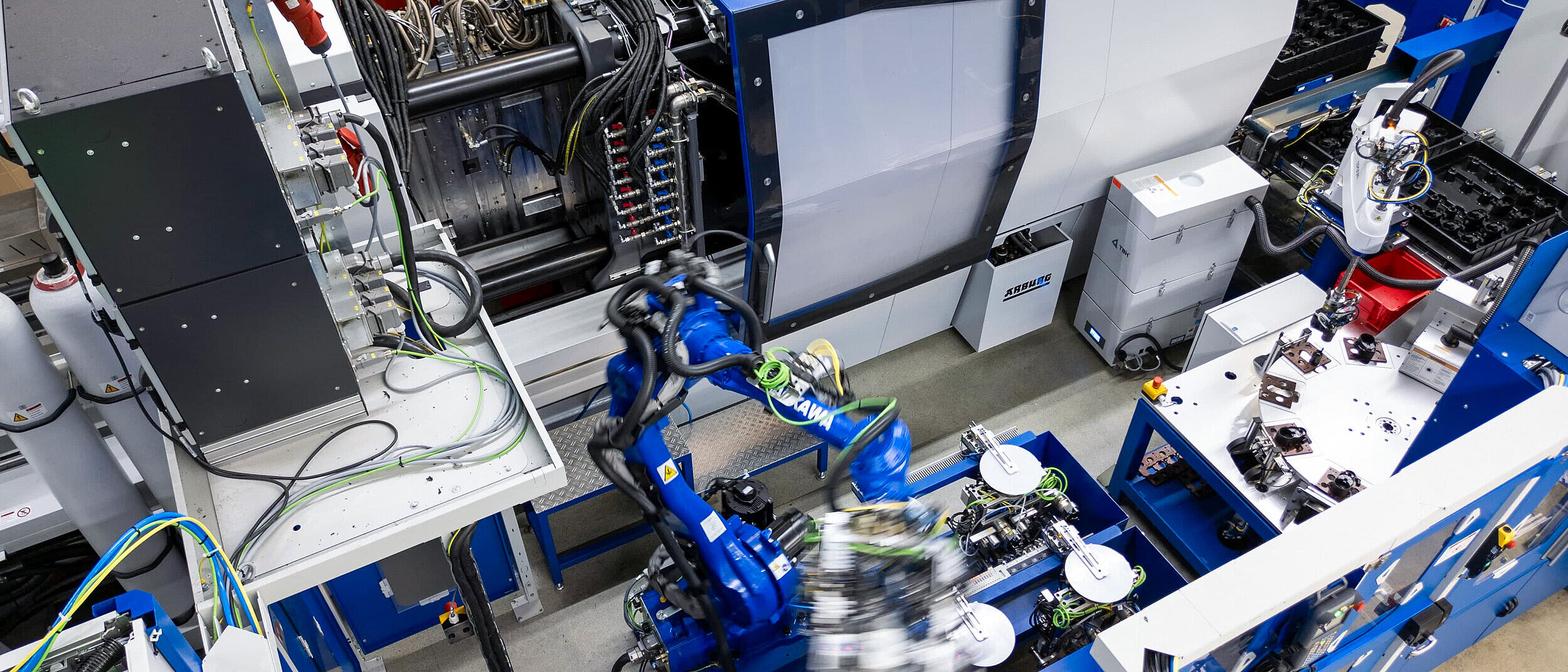

IEA provides a wide range of services with respect to the automation of manufacturing processes. It is based on a great wealth of experience with automated processes in the production of a great variety of metal and plastic components, with a key competence in the field of complex small parts. This competence is reflected by three columns: